Restoration & Renovation

A Dome for All Time

Project: Restoration of the U.S. Capitol Dome, Washington, DC

Architect: Stephen T. Ayers, FAIA, LEED AP, Architect of the Capitol; Joe Abriatis, Dome Restoration Project Manager; Shane Gallagher, Dome Rotunda Project Manager; Tom Nowell, Lead Construction Inspector for Dome Restoration; Alex Tayag and Bobby Oppermann, Construction Inspectors

The restoration of the historic cast-iron dome on the U.S. Capitol has recently been completed. This monumental $97-million, three-year effort to restore the exterior, interior, and Rotunda involved months and months of planning, plus hundreds of skilled artisans working at heights that would make most of us faint.

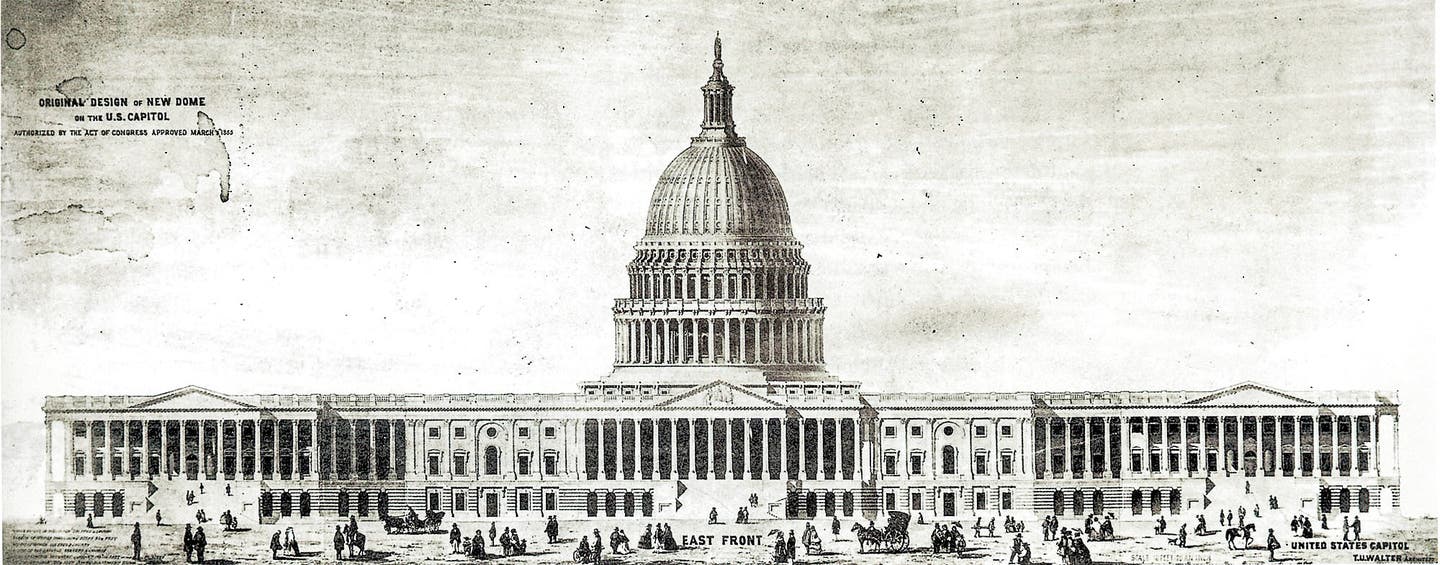

This is just the latest in a long line of historic events for the Capitol. The cornerstone was laid in 1793, a copper dome was completed in 1824, and when wings were added in the 1850s, it was decided that the copper dome was too small. The existing, larger dome was built from 1855-1866, (continuing during the Civil War).

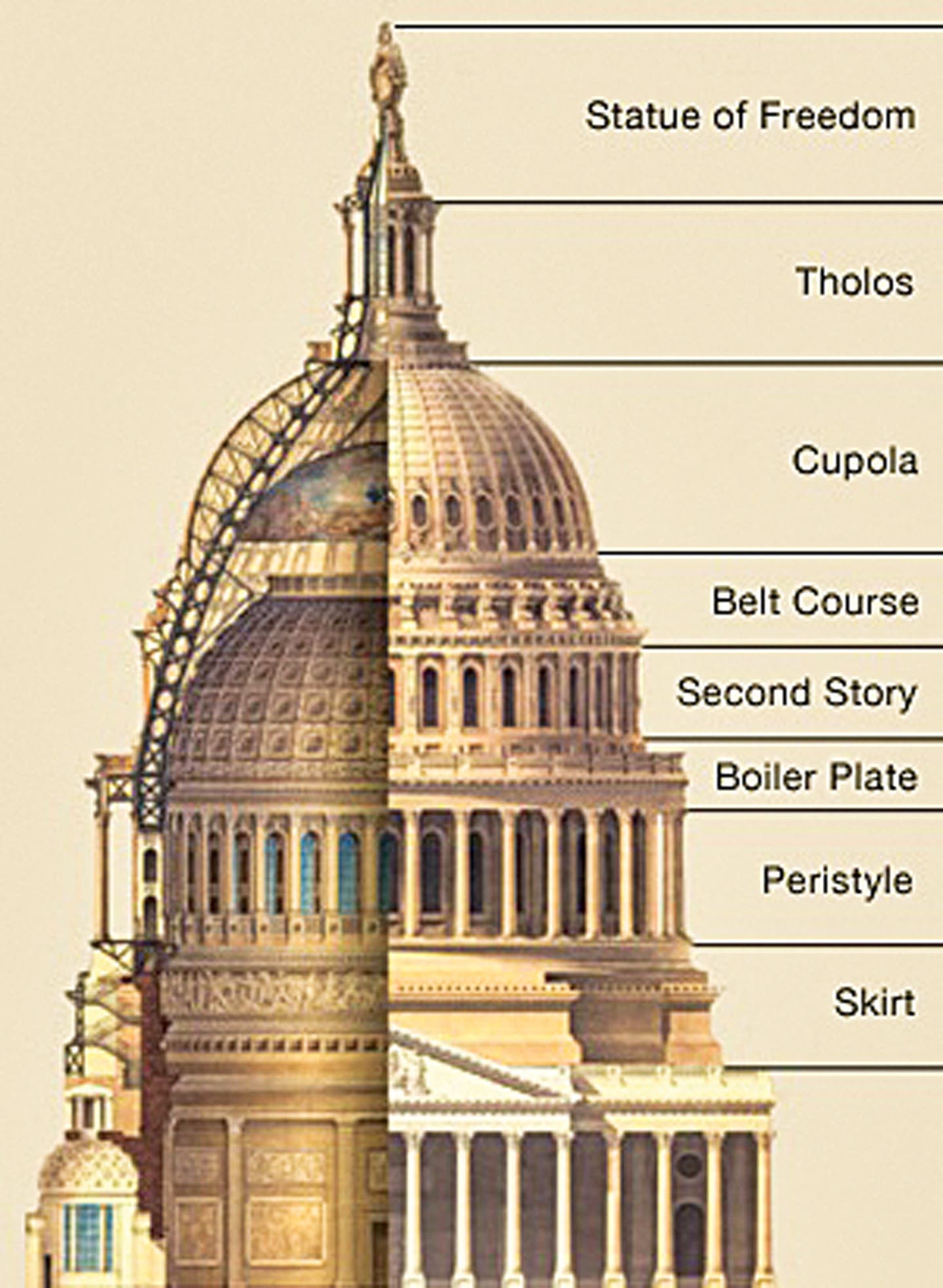

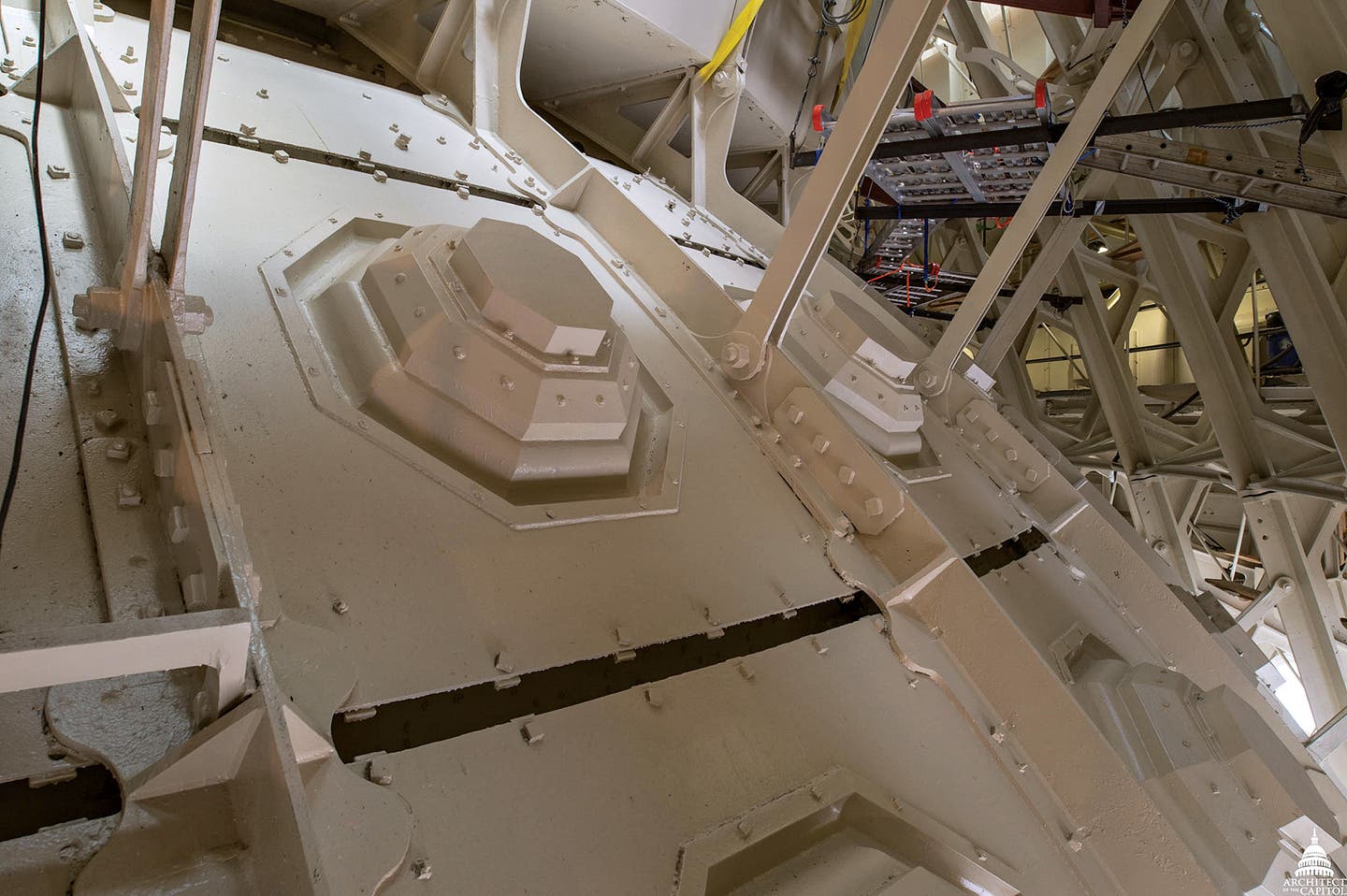

The 9-million-pound cast-iron dome is 199-ft. tall (from the skirt base to the base of the Freedom statue) and rises 288 ft. (including the Statue of Freedom) above the East Front Plaza of the Capitol, making it the tallest cast-iron dome in the world at the time. It measures 135 ft. in diameter on the exterior, 96 ft. on the interior and is actually two cast-iron domes connected by a truss system and painted to look like stone.

The historic dome had been showing its age for several years. A previous restoration in 1959-60 was no longer holding up. More cracks were showing up and pieces of cast-iron were falling off the building.

“This is a once-in-a-generation project,” says Stephen T. Ayers, FAIA, LEED AP, Architect of the Capitol. “It hasn’t been done since 1959-60. It is certainly important; you can hardly turn on a TV or any media anywhere in the world without seeing the Capitol in the background. It is the symbol of our country, so we wanted to do everything possible to make it successful, to deliver for the American people. It is their building after all.”

“There was a lot of public attention,” he adds, “an enormous amount of attention from Congress and the public. Many years ago my team said we have 200-300 cracks and deficiencies, by the time it reached over 1,000 cracks it was time to intervene. We were losing too much historic material. Congress understood how important it was and quickly funded the restoration work.”

Before the work started, the office of the Architect of the Capitol (AOC) completed a pilot phase where they did a complete retrofit on a small section of the cast-iron dome. “We could see a series of visible cracks and deficiencies,” says Ayers. “The pilot project showed us what we didn’t know. We found deficiencies and other cracks that were hidden. This enabled us to test our repair techniques and measure effectiveness and production rates and to make subsequent estimates and plans.”

What they discovered were more than 1,000 cracks (approximately 8,000 inches) underneath approximately 12 layers of paint, and hundreds of pieces of cast-iron ornament that had rusted and/or fractured and were in danger of falling off the building.

The contract was awarded in 2013 and work started in 2014, with the closing of the Rotunda for a few weeks to add netting to protect visitors and art from falling debris. Then a one-acre staging area was set up at the northwest corner of the Capitol. The next step was to build the scaffolding; this included 52 miles of scaffold piping on 25 levels with two miles of decking, around the exterior of the dome. The dome’s many layers of lead paint were then removed and two coats of paint were applied.

Repairing the many cracks in the cast iron was a complicated process. First pits with no cracking were filled with epoxy. Then, since cast-iron cannot effectively be welded in situ, a system called lock-and-stitch was used to repair the cracks. It involved drilling holes along the length of the crack and inserting steel pins with heads that slightly overlap, creating a watertight seal. The heads are broken off creating a smooth surface, and then steel locks are inserted across the cracks to strengthen the seal and pull the metal edges together. Most of this work had to be done at night so the noise would not disrupt the Capitol.

In addition, the cast-iron ornament required quite a bit of work. Cast iron has a long history, according to Robert Baird, president of Historical Arts and Casting, of Salt Lake City, UT. It dates back to the fifth century in China and it was used to build a monastery as early as 200 BC. In 1797, the first cast-iron building was built in the UK. In the U.S., the first cast-iron dome was completed in 1864 on the St. Louis County Courthouse and the U.S. Capitol dome was completed during the Civil War, without the use of electricity or power tools.

Baird cites several problems that had to be addressed: fractures caused by the freeze/thaw cycle and by corroded and broken castings; rust jacking (water damage causes rust and as the rust grows, it forces pieces off of the building); dissimilar materials and electrolysis (bolts and fasteners were handmade of wrought iron and when water gets into the fasteners, it causes cracks and then corrosion.)

The entire Tholos balustrade just below the Freedom Statue, smaller items such as grape clusters and acorns, and larger pieces such as column capitals and antefixes were removed and repaired. The largest ornaments removed were the 36 50-in. tall antefixes, weighing 600-700 lbs. each. There were also 72 giant acorns that were dis-assembled, abrasively blasted, and repaired or replaced.

Hundreds of individual pieces were repaired, including the scores of individual pieces in each of 4-ft. tall capitals on the 36 Corinthian columns. Thousands of pounds of cast iron in the 9-million pound dome, as well as 5,000 to 7,000 stainless steel fasteners were ultimately replaced.

A significant part of the project was replacing the inner gutter system under the boilerplate balustrade. It had filled with rust, allowing water into the building. The entire gutter (50 11-ft. sections) was removed, rebuilt in the foundry and re-installed. The new pieces were hoisted up 8 levels of scaffolding and re-assembled. After replacing the gutters the boilerplate balustrade was reassembled.

Finally the repaired and restored dome was repainted with a color known as Dome White.

Windows on all three levels—the cupola, the second story and the peristyle—were also repaired or replaced as needed. There are 108 windows in the dome, 36 in the cupola, 36 in the second story and 36 in the peristyle. Five of the cupola windows had to be replaced, and the team was able to find a supplier who could make glass in the same way it was made 150 years ago, to match the original wavy glass. Wavy glass was replaced at the peristyle and second story levels.

Meanwhile the interior rotunda was also restored. “We started with a detailed documentation of the paint history of the interior cast iron,” says Mary Oehrlein, FAIA, Historic Preservation Officer, Architect of the Capitol. “Nothing had been stripped in the past, so we were able to take thousands of samples to get the full history. We found that it had only been painted four times, approximately every 40 years.”

Then all of the paint (it was lead-based) was stripped and the cast iron portion of the interior was repaired. There wasn’t nearly as much damage as on the exterior.

Other repairs on the interior included updated lighting, mechanical ventilation and cleaning and dusting the lower limestone walls. In addition, the frieze was conserved.

Ayers had high praise for the people who worked on the dome. “The craftsmanship was genuinely true to the original,” he says. “And the contractors and subcontractors that took on this job were genuine specialists in this kind of work. It was delightful to know that this level of craftsmanship is evident in the country today, that we can still make our grand old buildings look great again.”

While much of the work—sand blasting and painting—had to be done at night to avoid noise in the building, most of the ornament work could be done during the day. At any given time, there were approximately 100 people working on the dome in two shifts. Historical Arts had 12 on site and another 20 working in the foundry. Baird adds, “This was a high-profile project so there was lots of security and oversight. Getting materials on and off the site was complicated.”

This recent restoration was well documented. “We understand in this building and the other 35 other structures we manage, that we are making history every day,” says Ayers. “We document and archive everything that we do day in and day out, through photography, videography, keeping all documents. That’s an important part of our work.”

“We know this building will be here 100 years from now, and they will rely on our documentation just like we are using the information that was archived 150 years ago,” he adds, “The photography is primarily documentary but it is also to help celebrate this grand dome.”

“The project was completed ahead of schedule and under budget,” says Christine Merdon, Chief Operating Officer, Architect of the Capitol. “95 to 98 percent of the dome is still historic fabric. The goal was to save everything that could be saved. It was a collaboration of all the trades.”

A Brief History of the U.S. Capitol Building's Dome

1792 – U.S. Secretary of State Thomas Jefferson called for a competition to design the Capitol. A design by Dr. William Thornton was selected. It was later modified by Benjamin Henry Latrobe and then by Charles Bulfinch.

1793 – The cornerstone was laid.

1800 – Congress, the Supreme Court, the Library of Congress and the courts of the District of Columbia moved into the north wing.

1811 – South wing completed.

1814 – The British set fire to the Capitol. Architect Charles Bulfinch replaced Latrobe and completed the chambers for the Supreme Court, the Senate and the House by 1819.

1824 – Copper dome completed under Bulfinch.

1850s – The Senate and House wings were added. They were designed by Thomas Ustick Walter and August Schoenbom.

1864 – The current cast-iron dome was completed at a cost of $1,047,291 in 1866. Designed by Thomas Ustick Walter, it was built during the Civil War, at a time when there were no power tools. Cast iron was selected because of its fire resistance, light weight and ability to last.

The Capitol has been renovated often: 1793-1826 was the initial building; 1851-1868, first major renovation; 1958-62, renovation; 1993, West front; 2008, visitor center opened; 2011, Phase 1 of the dome; 2016, dome restoration completed.

By the Numbers

Stephen T. Ayers, FAIA, LEED AP, is the 11th Architect of the Capitol. The AOC’s 26,000 employees manage 17.4 million sq.ft. of building space in 37 structures on 580 acres, as well as thousands of works of art.

Dome size height is 199 ft. from the base of the skirt to the base of the Freedom Statue; exterior diameter is 135 ft.; interior diameter is 96 ft.

Paint removed, exterior

Approximately 12 layers

Number of cracks repaired

8,000 in. using lock-and-stitch technique

Paint, exterior

1,215 gallons of Dome White

Ornament

36 sections of Boiler Plate balustrade; 72 acorns weighing 80 lbs. each; 36 grape clusters

Columns

36 in peristyle; 12 in Tholos

Statue of Freedom

19.5 ft. tall; 15,000 lbs.