Product Reports

What Makes a House a Home?

To this age-old question, there is, of course, no single answer. But we all know that everything starts with the good bones of architecture.

The meat of these bones comes from a variety of interior finishes—windows, mouldings, flooring, lighting, hardware and fixtures and fittings—that add warmth, style and personality to the spaces we love to live in.

Bringing a house back to its prime time or creating a new-old house can present a challenge because there simply isn’t a huge supply of artisans who are still practicing old-world techniques.

Today, the interest in artisanal craft has been revived, and those who have mastered such skills are in high demand and intent upon passing their craft down to the next generation.

Here are some of the companies that have taken tradition to heart, creating the legacy elements that take architectural bones from bare to beautiful.

Lighting

Aurora Lampworks

Involved in a variety of national and international projects, Aurora Lampworks restores vintage fixtures and creates contemporary ones.

The Brooklyn-based company traces its roots to 1978, when founder Dawn Ladd bought a mauve lampshade in England and decided to create more vintage shades. Along the way, she started rewiring fixtures.

The company, whose first major commission was restoring the fixtures on Yale’s Old Campus, has worked on many high-profile projects. Its clients have included the Brooklyn Paramount Theatre, David Geffen Hall and St. George Theatre in Staten Island, New York.

“Each week, extraordinary fixtures from all over the world make the journey across the ocean to our loading docks,” Ladd says, adding that some members of her team have been with the company for decades. “European hanging standards vary greatly from those in the United States. It’s our task to bring them to U.S. and UL standards, which can include inspecting, restoring, rewiring and UL listing them.”

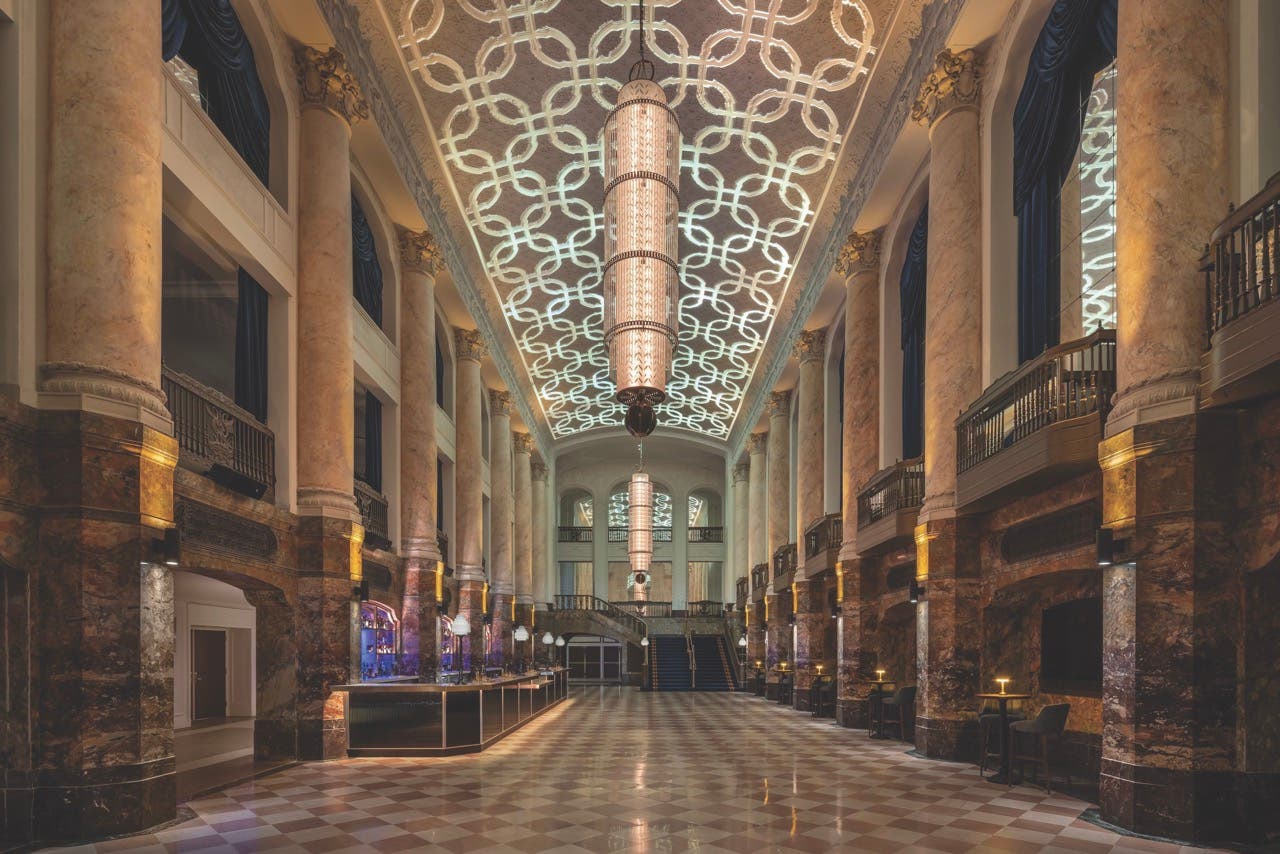

BELT

Blending artistry, craftsmanship and design, BELT creates bespoke metalwork for luxury projects, including private residences, places of worship, leisure spaces and commercial developments.

The handmade pieces, which range from lighting fixtures to windows and doors and staircases, combine traditional techniques with modern expertise.

“We are dreamers, artists, designers and masters of our craft who create truly unique pieces,” says Louis Beltran, the company’s self-styled maestro and CEO who conducts a multidisciplinary team of more than 180 experts. “Each project is tailor made; it’s a collaborative journey with architects, interior designers, builders and clients.”

The second-generation family-owned company, founded 40 years ago and based in Florida, makes what Beltran calls “timeless creations tailored to each client’s vision.”

Beltran sees challenges as “opportunities to push boundaries and do things other companies wouldn’t dare to do. We thrive on exploring the endless possibilities of metal. We are equally excited to work with complementary materials like wood, textiles, marble and renewables such as bamboo, which is one of our latest explorations.”

Noting that BELT’s core mission is to “create unique pieces that will transform the spaces they will occupy,” Beltran says that the company’s legacy lies in “delivering happiness” through pieces that will stand for generations.

Heritage Metalworks

Heritage Metalworks’ handcrafted lighting fixtures are made in house using original tools, methods and finishes. The two lighting lines—Scofield Lighting and Heritage Traditions Lighting—complement the company’s authentic, hand-forged and cast-brass period hardware that is sold under the brand name HMW Forge.

The company’s award-winning team, which is 16 strong, adapts standard fixtures, fabricates based on inspiration or translates concepts into new designs at the on-site foundry, blacksmith’s shop and metal-fabrication business.

“Basically, if it involves metal, we can build it,” says founder and owner Matt White, who set up shop a quarter century ago.

The fixtures are available in a variety of finishes, including living patina, rust-resistant aging, hand-forged textures and polished or antiqued designs.

Last year, Heritage Metalworks introduced The Scofield Lighting Anniversary Collection, which adds designs to those created 50 years ago by Richard Scofield.

In addition to lighting, Heritage Metalworks creates custom architectural metalwork, including furniture, fireplace surrounds, range hoods, countertops, decorative objects, gates and railings, and has been tapped to work on projects at a variety of iconic institutions, including the U.S. Capitol and Winterthur Museum, Garden and Library.

Manning Lighting

A three-generation family-owned company, Manning Lighting just celebrated its 75th year of creating handcrafted decorative lighting for distinctive architecture, including houses of worship.

The company, which has completed more than 70,000 installations around the world and has more than 80 sales reps in the United States, Canada and Mexico, offers hundreds of stock fixture options as well as custom lighting.

“We are a real manufacturer—most of the parts and pieces are designed and built right here at our facility in Wisconsin,” says President Andy Manning, whose grandfather founded the company in 1948. “That allows us to propose modifications or build custom fixtures that truly harmonize with the architecture they will live in.”

Noting that he and his 25 employees—engineers, welders, painters, assemblers, machinists, designers and custom-service professionals with decades of experience, are proud “lighting geeks,” Manning says that “we are fortunate to work with some immensely talented people. When we can take an architect’s, lighting designer’s or building owner’s vision and make it come alive, it’s very rewarding.”

Flooring

Aalto

The artisans on staff at Aalto design create custom marble inlays based on the company’s extensive archives or the client’s custom specifications.

“We can create inlays in many styles from historical replica to contemporary,” says President Annie Aalto. “Our three-decade history of sourcing marbles from around the world enables us to acquire and fabricate myriad colors, tones, finishes and styles.”

The founder of the family-owned company, based in Iowa, pioneered the use of waterjet technology for decorative stone and developed a line of focal medallion designs that, according to Aalto, have since defined the look of the modern stone floor medallion.

“We created whole-floor concepts using medallions, borders and accents to integrate the formal areas of the home,” Aalto says. “Such designs incorporate free-floating elements and open-ended borders, creating continuity throughout the open spaces of today’s luxury residences.”

She adds that new advancements in technology have allowed the company to create designs that have more detail and accuracy that incorporate colors of marble, semi-precious stone and quartzite that have never been available before.

“We are taking an ancient art form and realizing it for today’s interior spaces,” she says.

Chestnut Specialists

A boutique supplier of antique reclaimed flooring and lumber products in white oak, chestnut and pine, Chestnut Specialists is a third-generation family business that has been working in the field for 35 years.

President Dave Wasley, son of the founder, started working at the Connecticut-based company part time shortly after graduating from college and never left.

“I fell in love with the unique beauty of antique lumber, particularly chestnut,” says Wasley. “Chestnut is nearly completely extinct, typically falling to blight before reaching maturity. Now it is only available as a re-milled/recycled product. We handle each board up to 12 times in our process, and it is a labor of love to watch the gorgeous grain emerge from old lumber.”

E.T. Moore Manufacturing Inc.

For 55 years, E.T. Moore Manufacturing has been supplying reclaimed heart pine flooring, beams, mantels, mouldings, millwork stock and stair components, working with top architects, contractors and nonprofits to restore historical homes, museums and even boats that date from the 17th to the 20th centuries.

The company’s inventory, which is housed in a 5-acre building on a 30-acre property in Virginia, “is second to none,” says Taylor Moore III, whose father founded the family-owned and -operated company in 1969. “It allows us to have one of the fastest industry lead times.”

E.T. Moore can match building components, from shingles to beams, flooring, wall paneling, door and window materials, beams, mantels, stair components and siding and mouldings with historically accurate materials for repairs, renovations and additions.

“We can even ‘start from the log,’” Moore says. “If your specs are beyond what is available in traditional markets and suppliers, we can purchase the logs, saw to spec, dry to spec and mill to spec. The impossible is always possible here with enough time and budget.”

Old Wood Workshop

Started in 1991, Old Wood Workshop specializes in 18th-century and early 19th-century original-surface flooring, beaded and feather-edge wallboard and primitive stone landings and stone posts. It also has a curated selection of primitive wooden and stone decorative art for the garden and interior décor.

“I salvage and buy only the best quality and one-of-a-kind items with history, character and patina,” says Thomas Campbell, who along with his wife, Cris, started the company over 30 years ago. “I do not supply any re-sawn material and only sell original-surface flooring and wallboard—hand planed or foot worn.”

The Campbells, who run the Connecticut-based company as a two-person show, started their business with an old Subaru wagon, a chainsaw and a 100-foot-long chain. Their first salvage job was pulling down a decrepit orchard barn.

“Every day is a treasure hunt,” Campbell says. “Our focus is to provide our clients with a product that is unique, high quality and that they will cherish for a long, long time. They often come back, even years later, asking us to help them with their next antique wood or stone project.”

Fixtures and Fittings

Bathroom Machineries

A one-stop shop for hard-to-find vintage bathroom and plumbing supplies, Bathroom Machineries specializes in the restoration of period fixtures and the supply of obsolete parts.

The family-owned and -operated business, which has a half dozen employees, has been in operation since 1976, when its prime focus was on water-saving fixtures.

“So many plumbers tell their clients that repair parts for their older fixtures are not available, and that’s simply not true,” says Lydia Scheller, the owner’s daughter. “It is incredibly satisfying to work with customers to find the correct parts to keep their vintage bathrooms or kitchens working.”

In addition to working with plumbers and homeowners, Bathroom Machineries, which is based in Murphys, California, collaborates with historical preservation organizations on large-scale projects. “Restoring fixtures back to their beautiful, original state or finding historically correct parts is one of the best parts of my job,” Scheller says.

P.E. Guerin

Established by French immigrant Pierre Emmanuel Guerin in 1857, P.E. Guerin is one of the oldest hardware manufacturers in the United States, and its fixtures and fittings grace some of the country’s most impressive historical buildings, including the Biltmore Estate and Fair Lane, the Henry Ford Estate.

P.E. Guerin’s stock and made-to-order lines cover every design period from 18th-century French and English through Deco and Modern, and the studio’s library of patterns numbers 100,000 pieces.

“We have the ability to make anything right here in our New York City factory,” says Martin Grubman, vice president of the fourth-generation family-owned business. “We are the only firm to make hardware by hand at the highest level in the United States using traditional sand-casting, chasing and turning techniques. I feel the need to keep this art form alive.”

Mouldings

Driwood Moulding Co.

A maker of architecturally period-correct embossed mouldings,

Driwood has been in business for nearly a century.

Founded in Brooklyn in 1940, the company, which describes itself as a “family of makers,” prides itself on making beautiful, lasting period mouldings and architectural millwork —and long-term relationships with clients.

Driwood’s stock mouldings, which are made of poplar, are suitable for staining or painting. Driwood also manufacturers mouldings to order in walnut, maple, oak, cherry, mahogany or any other wood that the project requires.

Unlike costly hand-carved mouldings, Driwood’s products are affordable, making them appropriate not only for residential use but also for large-scale commercial projects.

Designer William Wood, who has been with the company for more than 40 years, continues to be inspired by “traditional architecture and the skill required for such artistry.”

He calls the relationships he’s built with clients over the decades “truly remarkable. We create lasting connections and bring our clients’ dreams to life.”

JP Weaver Company

Established 111 years ago by an English master carver and gilder, JP Weaver Company is a premier designer and maker of elegant interior architectural ornament that has been featured in Hollywood movies and has been installed in prestigious projects as far away as China, Greece and Saudi Arabia.

The family-owned company, which has 15 full-time employees, revived the lost art of producing ornate architectural moulding reminiscent of the elegance of Versailles when such designs fell out of favor in the 1970s.

JP Weaver, which uses a classic trade-secret recipe to create compo, offers complete design services from concept to completion as well as an extensive selection of stock parts. Its ornamental mouldings are made in gypsum, flexible resin and composi tion. It also restores plaster and composition components on picture/mirror frames and fireplace mantels for local clients in Glendale, California.

Its Petitsin Line is renowned in the industry for its detail and quality and has been compared to the historical European ornament that inspired it.

“Interior moulding design is a field of endless challenges and puzzle solving,” says Senior Designer Stephanie Croce. “At first glance, we seemingly face impossible situations, and with perseverance and creativity, we create solutions that are beautiful and can be executed within the client’s budget. For these reasons, this non-work work is endlessly exciting and gratifying.”

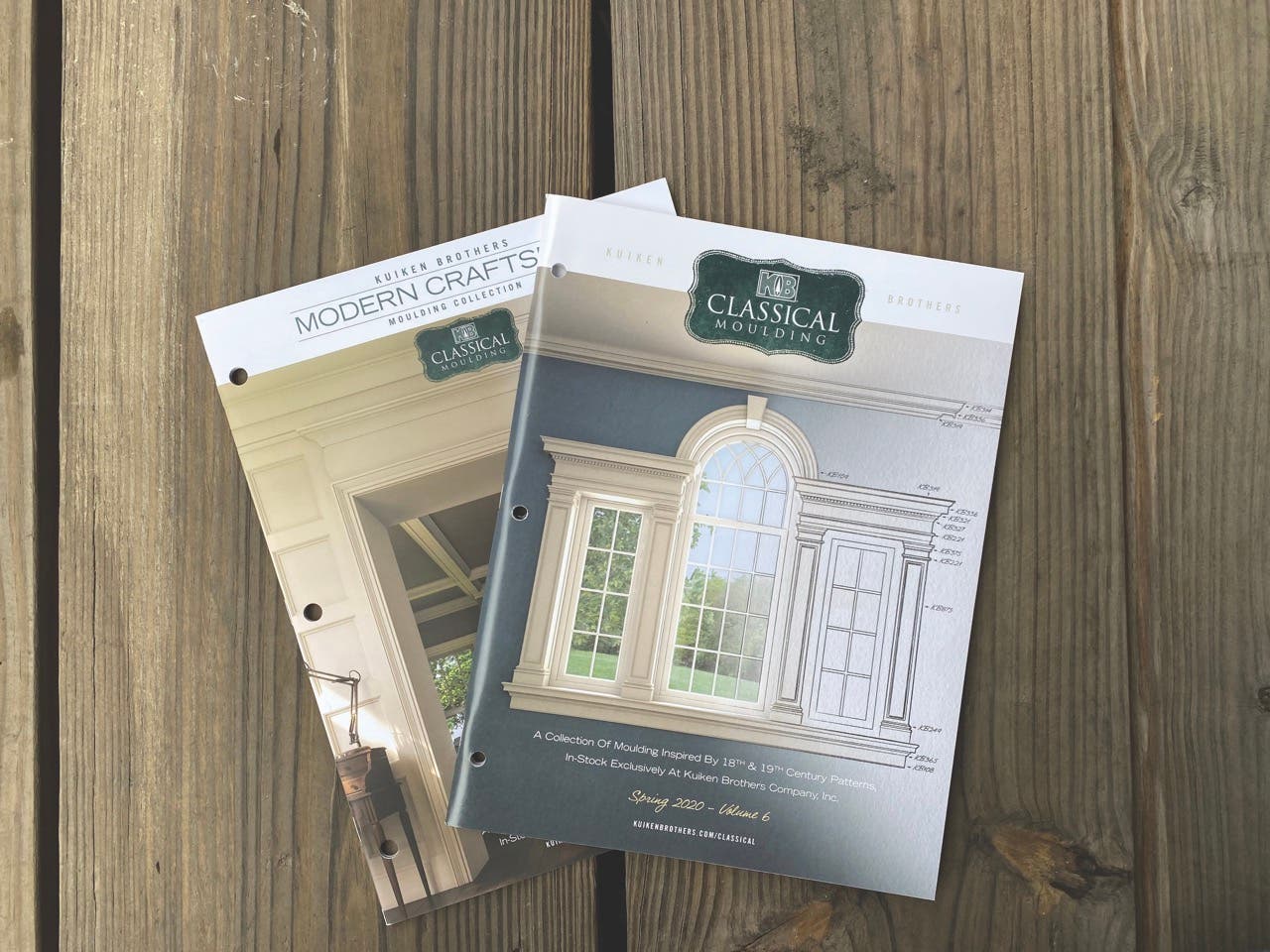

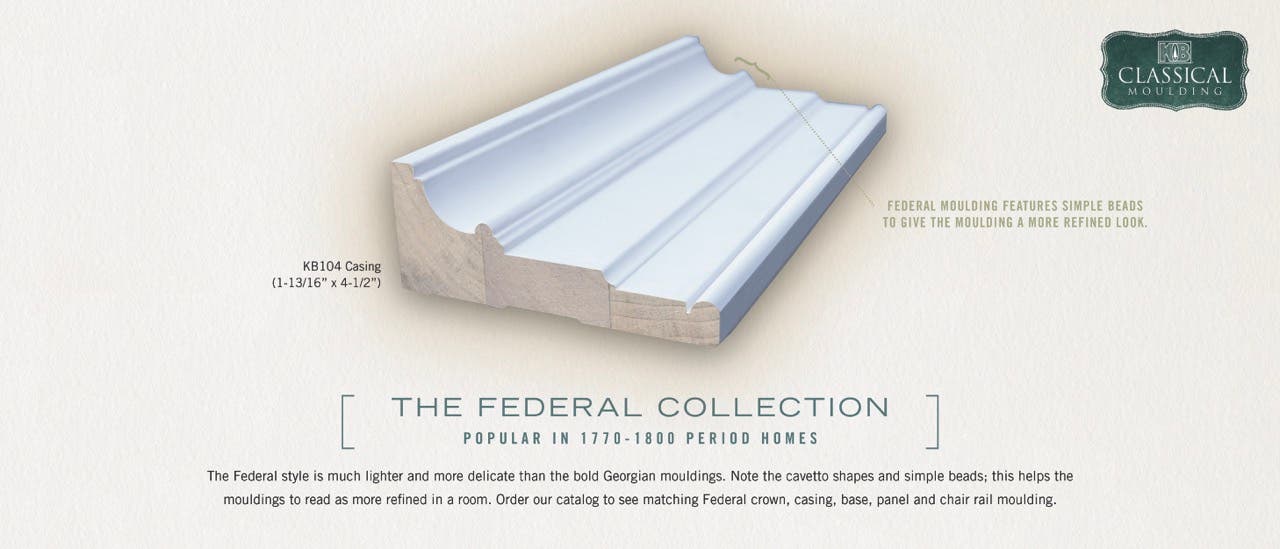

Kuiken Brothers Classical Moulding Co.

Established in 1912, Kuiken Brothers Co. has one of the largest in-stock collections of classic American moulding profiles in the United States.

The six collections, which number more than 90 moulding profiles, encompass Early American, Georgian, Federal, Greek Revival, Colonial Revival and Traditional Revival styles. Each collection has matching crown, casing, base and panel profiles, and each casing has proportionally scaled replicas that can be scaled down and a matching base cap to create custom heights.

“These profiles are not only designed to simplify installation but also provide a truly custom look, unachievable for most until now,” says Ryan Mulkeen, vice president of marketing and communications at the fourth-generation family company.

The in-stock mouldings come in 16-foot lengths. They are milled from Appalachian poplar, double primed and buffed.

The company, which is based in New Jersey and has nine locations, offers a variety of free downloadable resources, including a moulding design guide and a classical moulding catalog and pattern book.